Ensuring the safety and durability of concrete structures is of utmost importance. However, achieving effective concrete repair and maintenance can be hindered by various challenges. Despite concrete’s renowned durability, it is susceptible to wear and tear over time. Cracking, for example, is a common issue in concrete due to freeze-thaw cycles, structural stress, or chemical exposure, as well as constant loading and unloading cycles. Carbonation, chloride attack and moisture penetration into the concrete can also lead to corrosion of reinforcement, efflorescence, and spalling. Identifying and promptly repairing is necessary to prevent further structural damage.

Evaluating the structural integrity of concrete can be a complex task. Engineers must employ non-destructive testing (NDT) methods and inspections to accurately assess the condition of the concrete and determine the extent of repairs needed. Equipment such as Ground Penetrating Radar (GPR), Ultrasound scanners, Schmidt hammers, Impact echo devices, cover meters, strain gauge and Half-cell potential measurement complement each other to yield precise inspection results.

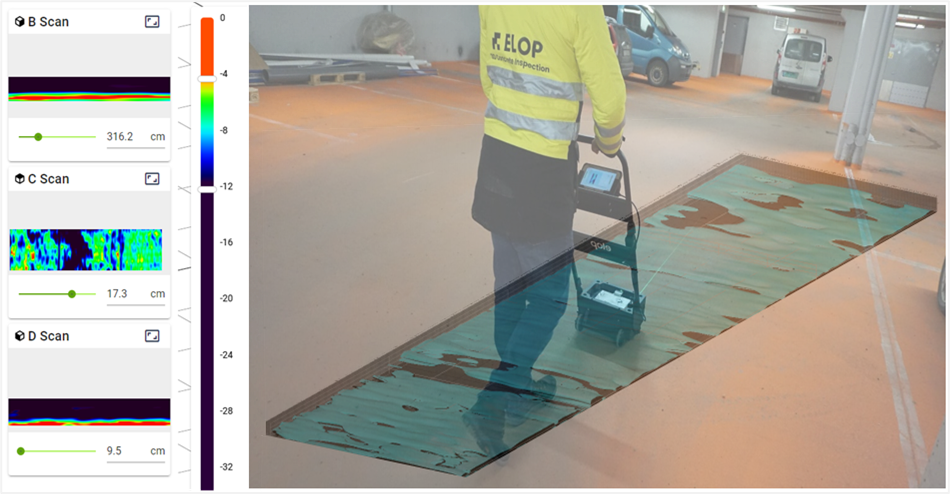

The Elop Insight ultrasonic scanner is a device that is designed to map concrete structures quickly and efficiently while rolling across the surface. This scanner employs dry coupling, eliminating the need for applying a coupling fluid on the surface, and can detect a wide range of internal features and defects such as cracks, delaminations, voids, honeycombing, and rebars. To achieve this, the scanner utilizes the Synthetic Aperture Focusing Technique (SAFT) algorithm for image reconstruction, which generates a detailed 3D model with enhanced tomographic views. Additionally, the scanner also provides valuable information concerning the relative distribution of sound velocity within the concrete structure. By measuring the velocity of ultrasonic waves, the Elop Insight scanner can effectively gauge the condition of the concrete. This invaluable data aids in identifying potential subsurface structural issues and defects within the concrete, enabling timely corrective actions to be taken.

Figure 1 A 3D reconstructed image of a parking garage obtained by Elop Insight scanner showing floor thicknesses for an area of about 10 square meter with shadows in some part of the image due to features closer to surface. Also shown in the figure are selected 2D slices (left) from the scanned volume.

In the world of concrete repair and maintenance, staying informed about best practices, innovations, and sustainable solutions is key. By addressing these challenges head-on, we can ensure that our concrete structures remain safe, functional, and reliable for years to come. Furthermore, extending the lifespan of structures also contributes to environmental preservation by reducing the need for new construction, which is a significant source of carbon emissions.