Ultrasonic testing – the perfect solution for detecting honeycombing in the concrete structure and helps ensure structural integrity.

Honeycombing in concrete is a result of the inability of the concrete to fill the available space, resulting in cavities, voids, and gaps between the aggregates that resemble the structure of a honeybee nest. Improper or excessive vibration during concrete placement, poor workability of the concrete mix, overuse of admixtures, use of a stiff concrete mix, excessive water-cement ratio, dropping of concrete from a height during placement, dense reinforcement at column-beam junctions, use of large aggregates in excessive amounts, poorly constructed and non-watertight formwork, and inadequate concrete cover are some of the causes of honeycombing. Honeycombs pose significant problems such as reduced concrete strength, the vulnerability of reinforcement to rusting, water penetration through the voids, corrosion of steel bars, reduced durability and lifespan of the structure, and poor appearance of the concrete surface. Ultrasonic testing is a well-suited NDT method for detecting honeycombing that is hidden inside concrete structures.

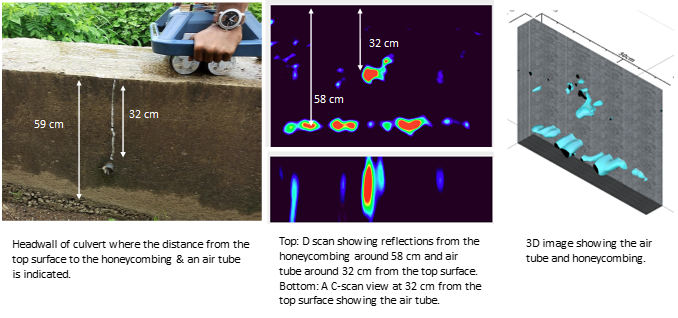

The Elop Insight scanner was used to detect honeycombing and other features in the headwall of a culvert where the inner part of the headwall intersects with the road embankment (Image above). The tomographic SAFT images generated by the scanner, along with a 3D image shown below, provided crucial information on the location and depth of the honeycombing. This information is essential to make a precise assessment of the extent of the damage, especially in cases where the honeycombing is not visible on the surface. The detailed and accurate information obtained from the scanner can facilitate appropriate repair or prevention measures, saving time and money in repairs and maintenance while ensuring the safety and durability of the structure.