Ultrasonic pulse velocity (UPV) testing is a proven non-destructive method for evaluating concrete quality and strength, but traditional probes are slow and limited for large-area inspections. The Insight scanner improves this by enabling fast, quantitative rolling ultrasonic scans over large surfaces using multiple wave modes to map velocity and estimate strength-related properties like dynamic elastic modulus. This allows rapid identification of low-quality zones, targeted follow-up with 3D tomography, and a major reduction in time, cost, and the need for destructive core drilling.

Ultrasonic testing is a widely used NDT method for evaluating concrete structures. It can also be applied to assess concrete strength by measuring ultrasonic pulse velocity (UPV). Repeated testing of ultrasonic pulse velocity at the same positions, as per ASTM C597, can monitor changes in the condition of concrete over time. The velocity of sound in concrete is correlated with its compressive strength and quality. An overview of sound velocity versus quality grading is shown in Table 1 below.

Table 1. Ultrasonic Pulse Velocity (UPV) criterion for concrete quality grading (IS:13311-1992-Part1).

| UPV value (km/sec) | Concrete quality grading |

| Above 4.5 | Excellent |

| 3.5 to 4.5 | Good |

| 3 to 3.5 | Medium |

| Below 3.0 | Doubtful |

While conventional ultrasonic probes have been used for this purpose, they are not suitable for large-area measurements, and strength evaluation has often relied on qualitative assessments or empirical models. In addition, two types of probes are usually required for such evaluations.

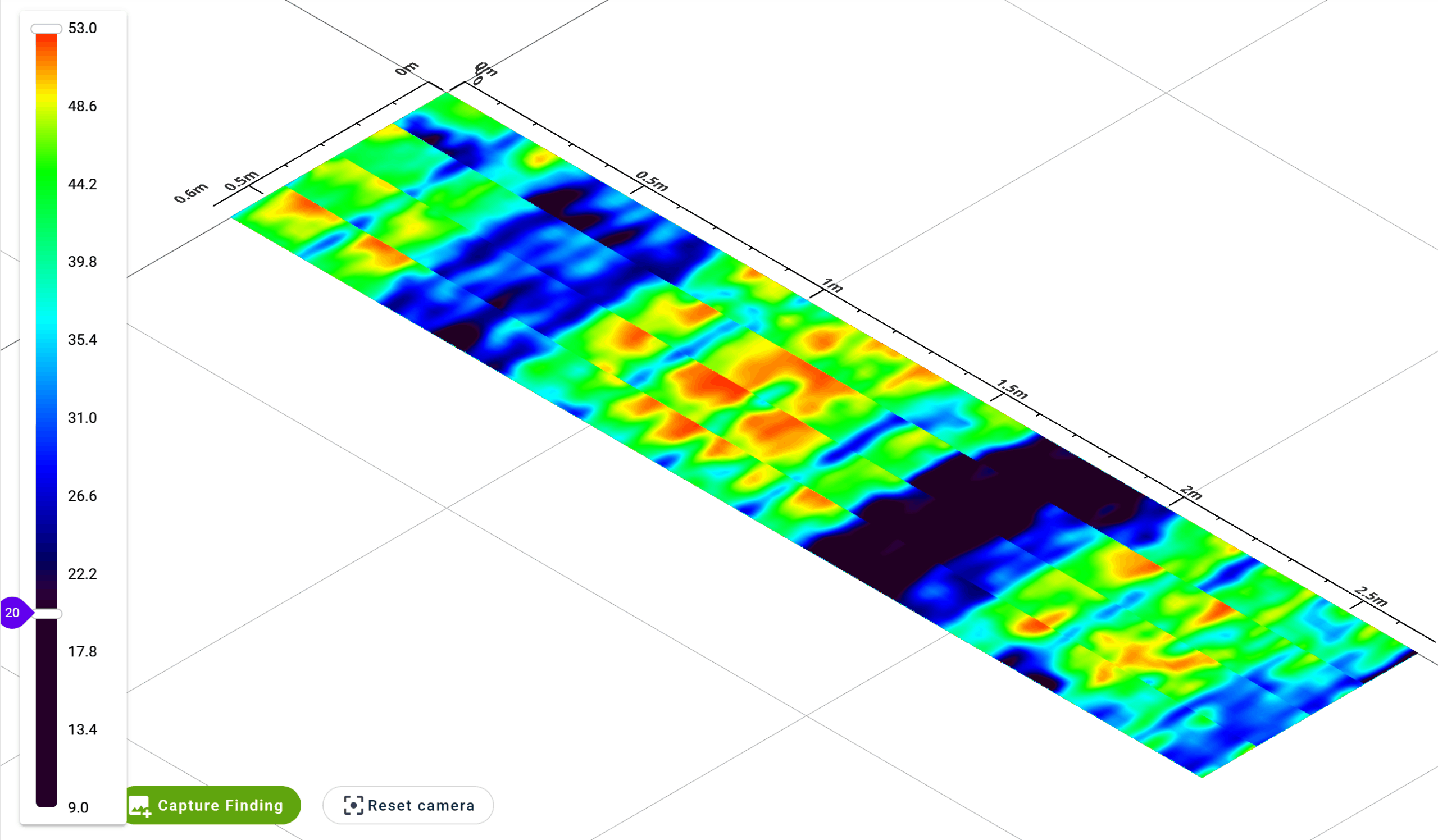

Figure 1. Area scan with velocity mapping mode obtained by Insight scanner showing the estimated dynamic modulus of elasticity for the scanned area of concrete.

Often, we encounter situations where we want to determine the quality of concrete, and although UPV provides useful indications, performing measurements over a large area is challenging. In the Insight scanner, we utilize two wave modes present to estimate strength-related parameters quantitatively and efficiently, as the scanner provides a rolling-ultrasound solution for concrete inspection. The physics behind the process is explained in detail here. Because a complete area can be scanned and quickly analyzed quantitatively, the system provides users with an overview of regions with relatively poor quality. The user can then focus on scanning those smaller areas in more detail using 3D ultrasonic tomography to obtain additional insight. By performing both velocity mapping and 3D imaging, the number of cores that need to be drilled and analyzed can be reduced significantly. This reduces both the time and cost required for large-area inspections.

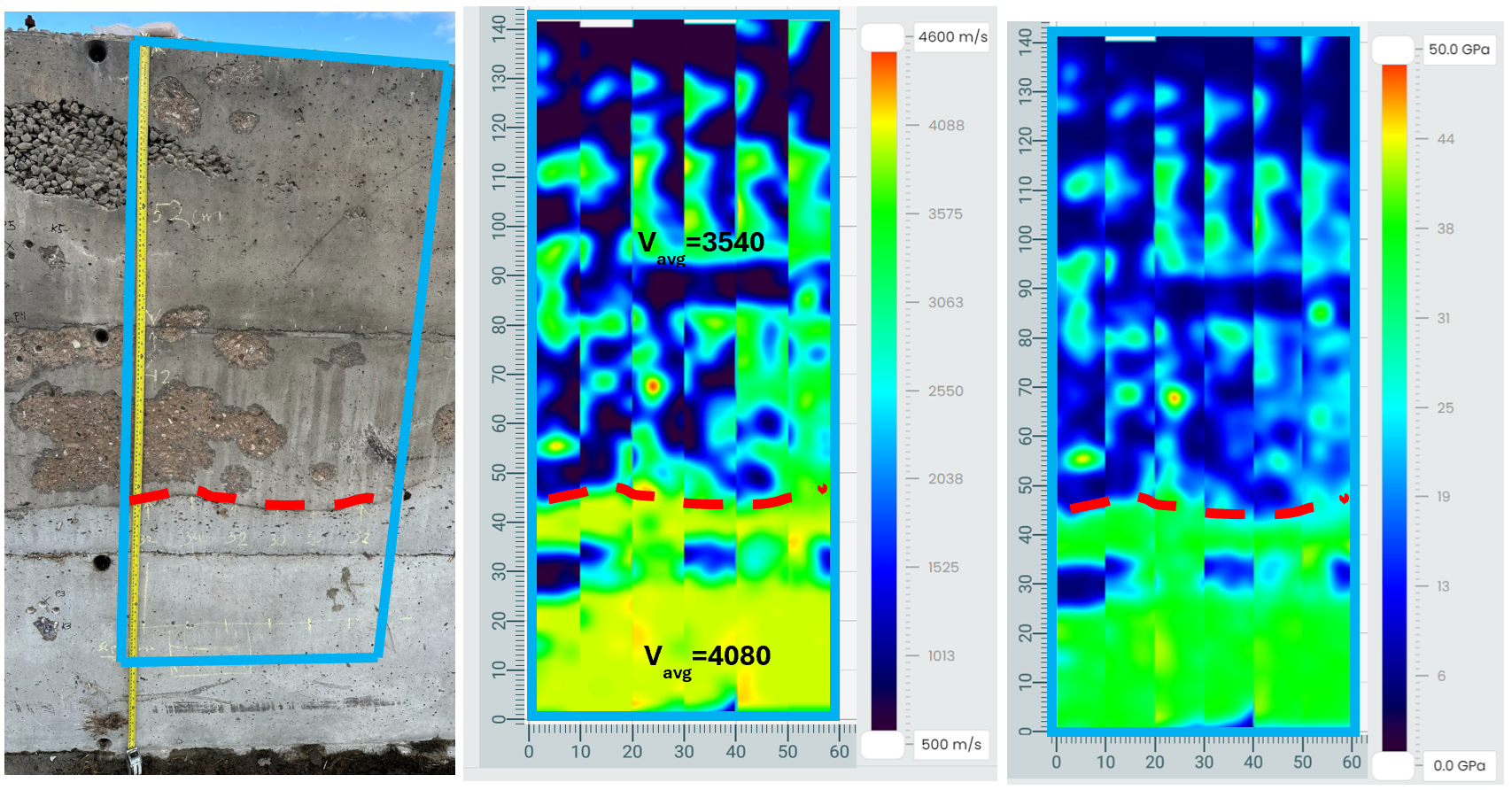

Below is a typical example of this feature in use. The scan was performed at a site where the concrete had been damaged by fire, and the task was to determine whether the fire had affected the concrete quality. The results are shown using the velocity and modulus-of-elasticity mapping feature available in Insight scanner.

Figure 2. The lower part (the less visually damaged concrete) shows reasonable sound velocities, mostly around 4100 m/s. In the upper part (the visually damaged concrete), only portions of the area have measurable velocity, and these values areas are significantly lower, generally around 3500 m/s and lower. The Modulus of elasticity map shows a similar trend, with values generally above 30 GPa in the lower likely “protected” part of the concrete, and a clear reduction to generally below 20 GPa in the areas that appear to have been more exposed to the fire.

Do you want to ensure the quality and the condition of your concrete structures? Contact us to learn how our advanced NDT solutions can help in your project.