Bridges are among the most critical elements of our infrastructure. As many of them age, hidden deterioration poses a growing risk to safety, budgets, and sustainability. Traditional visual inspections only reveal surface-level damage, while destructive testing is costly and limited in scope.

Elop Insight changes this. By enabling fast and efficient scanning of large bridge surfaces, it provides real-time 3D visualizations of the internal condition of concrete, helping asset owners and inspectors move from assumptions to facts.

Figure 1. Bridge over Mjøsa (Norway), only shown here for illustration purpose.

How Elop Creates Value for Bridge Stakeholders

For Asset owners and Managers

- Risk reduction: Early detection of internal defects —such as voids, delamination, honeycombing, and grouting failures in tendon ducts —prevents costly surprises.

- Data-driven decisions: Cloud-based access to scans, reports, and historical data supports long-term asset management and predictive maintenance strategies.

- Optimized lifecycle costs: By identifying the true condition of structures, unnecessary interventions can be avoided while ensuring critical issues are addressed in time.

For Inspectors and Engineers

- Efficiency: Rolling technology allows for the rapid scanning of large areas with consistent data quality.

- Clarity: Real-time 3D images, heatmaps, and sectional views (B-, C-, and D-scans) provide a clear understanding of subsurface features.

- Collaboration: Inspection data can be instantly shared and discussed with colleagues and asset owners through Elop’s cloud platform.

For Society

- Safety: Reduced risk of sudden failures by uncovering what is hidden inside bridge decks and beams.

- Sustainability: Extending the service life of bridges reduces the need for costly replacements and lowers CO₂ emissions from new construction.

Typical Findings on Bridges

Using Elop Insight, inspectors can identify:

- Cracks and delamination: Detecting issues hidden well below the surface.

- Tendon duct locations: Precise mapping, even under heavy reinforcement.

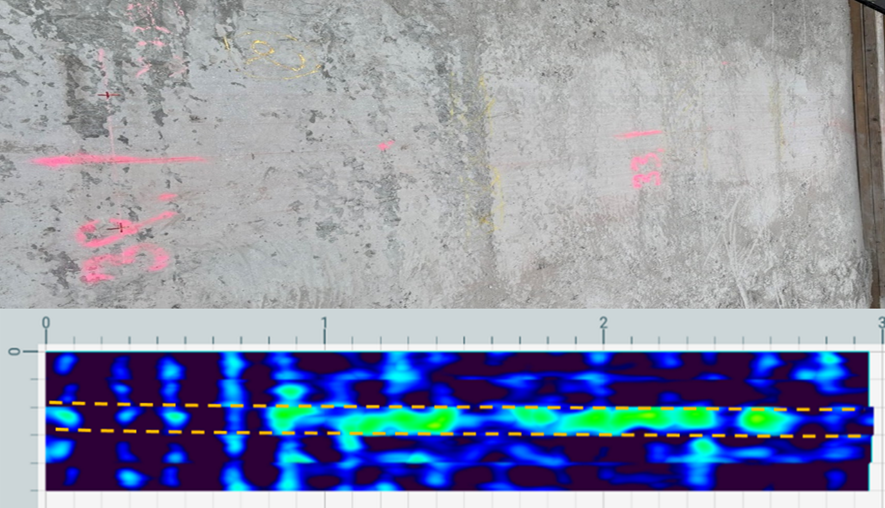

Figure 2. Scanned area of a bridge deck together with a C-scan from Insight scanner showing the position of the tendon duct.

- Voids and air pockets in tendon ducts: Identifying potential grouting defects.

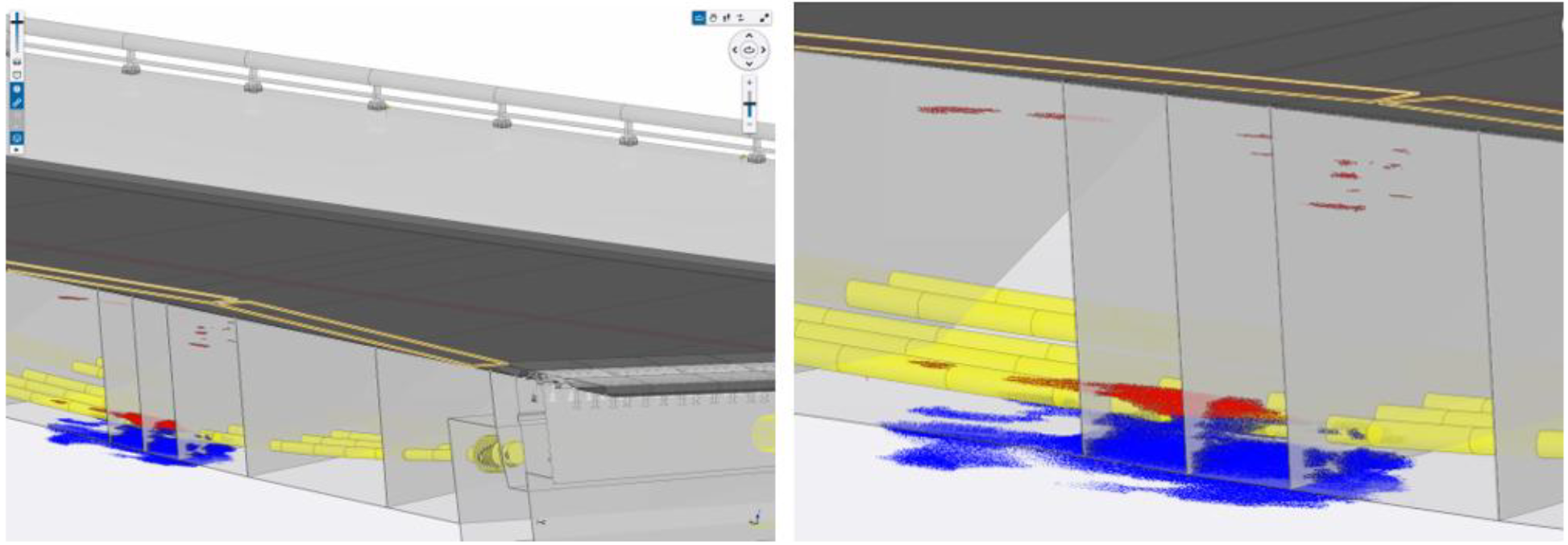

Figure 3. Scanned result from Insight scanner presented in a BIM model, cavities in the tendon duct visualized in red and backwall (concrete thickness) in blue.

- Thickness measurements: Verifying structural integrity of up to 2 meters by looking at backwall reflection.

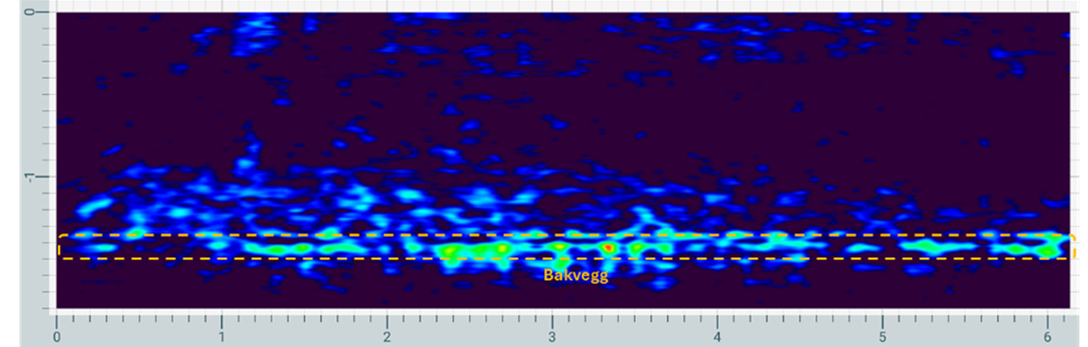

Figure 4. A backwall reflection on a bridge deck at 1.5 meters.

From Reactive to Proactive Bridge Management

By combining efficient ultrasound scanning with Elop’s cloud-based solution, bridge stakeholders have all inspection data safely stored and available when needed. This enables continuous monitoring, analysis, and smarter investment planning – ensuring bridges remain safe, sustainable, and financially viable for years and decades to come.

Contact us to learn more about this project and how Elop Insight can support your bridge inspection needs.

Contact us to learn more about this project and how we can support your bridge inspection needs.