– a performance comparison of non-destructive technologies for concrete inspection

White paper by: Prof. Dr. Björn Täljsten, Invator December, 2020

Introduction

Bridges, tunnels, buildings – concrete structures are everywhere around us, and we need to monitor them closely to secure their structural integrity. Critical infrastructures made of reinforced concrete have to be inspected regularly to assess how they need to be maintained, to ensure they’re safe, to extend their lifetime, reduce cost and – not least – to minimize their environmental footprint. With the inspection techniques available today, the maintenance and inspection of such structures takes a large amount of time. Hence, the operators need a quick, precise, and easy NDT technique for safe and smooth handling of these operations.

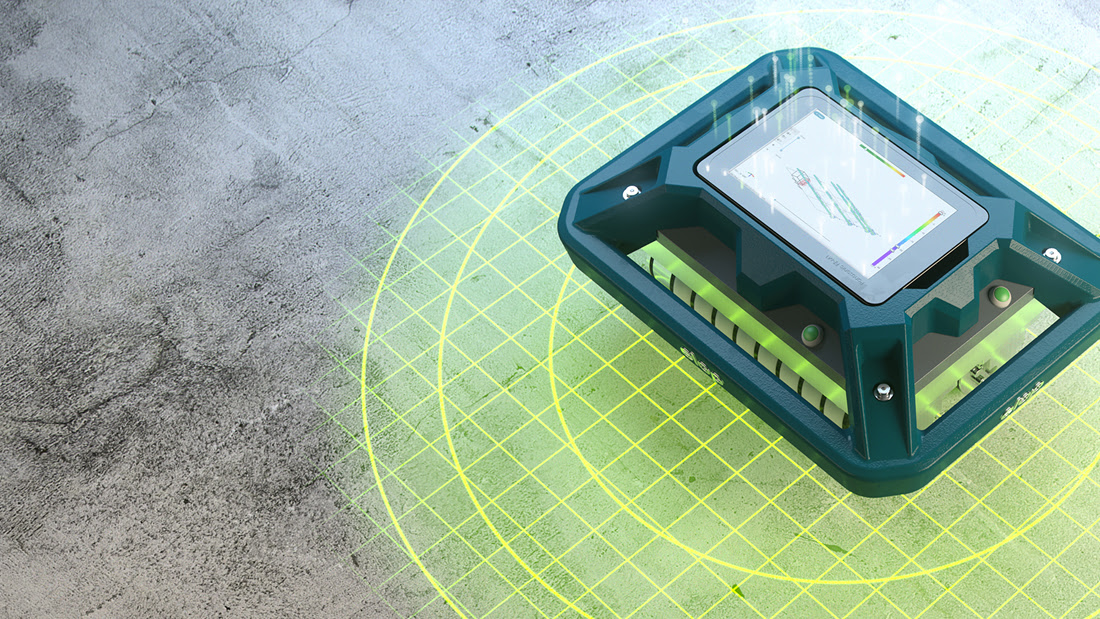

To meet this need Elop has developed a new and ground-breaking ultrasound measuring device, the Elop Insight scanner. Compared to conventional sub-surface inspection technologies the Elop Insight scanner can see more accurately beneath the surface of concrete structures, and it enhances precision in spotting for instance air pockets, cracks, rebars, and delaminations. In addition to this, Elop Insight is more than 10 times faster than conventional scanning techniques.

When the operator rolls the scanner across the concrete surface it captures data, which are merged in real-time into 3D-images providing a coherent visualisation of the structure beneath it. This allows for immediate interpretation and identification. Furthermore, the data produced by the Elop Insight scanner – images, 3D-video and documentation – are stored in the system and made available to stakeholders through a cloud interface platform.

However, this whitepaper does not focus on speed, 3D-images, or cloud interfaces. It offers an insight into the fundamental capabilities of Elop Insight, its performance, accuracy, and

not least repeatability of the measurements performed by it.