The Elop Insight technique

for non-destructive testing of concrete structures

White paper by:

Prof. Dr. Björn Täljsten, Invator

December, 2020

Introduction

Our modern society is strongly dependent on any means of well-functioning transport infrastructure, including roads, rail, water, and air. Besides this, we expect a reliable energy supply and long-lasting buildings. The most commonly used material for any ground infrastructure is reinforced concrete, and this trend will continue, growing the already enormous global production of concrete even further.

Even though concrete is so common, it is also susceptible to different kinds of deterioration processes and defects, as a consequence of improperly controlled production or construction processes, environmental conditions, cement composition, pollution, and even surrounding infrastructure, amongst other things. Examples of damages that these defects and deterioration processes might lead to are: cracking, reinforcement bond loss, voids, reduction of the cover layer thickness, corrosion, delamination, etc.

In the long run, if existing problems remain unaddressed, they will lower the performance level of the structure and eventually lead to unsafe structures, or even fatal accidents. Preventing that necessitates methods for regular assessment of the structural integrity to avoid problems that might lead to shorter service life. Having said that, maintenance of the asset can not only be planned, but also repairs and interventions can be precisely targeted and localized, retaining structural integrity and extending its lifetime, whilst at the same time ensuring the structure fully fulfils safety requirements. By all means, this has noticeable economic as well as environmental implications.

It is also important to mention both for our well-being and that of future societies is estimated that the construction industry is responsible for up to 40% of global energy consumption (1) as well as up to 40% of all waste creation (2). Furthermore, within the next ten years, the demand for global construction is expected to increase by 70% (3). In the light of these numbers, many have been looking for ways to move the industry in a more sustainable direction.

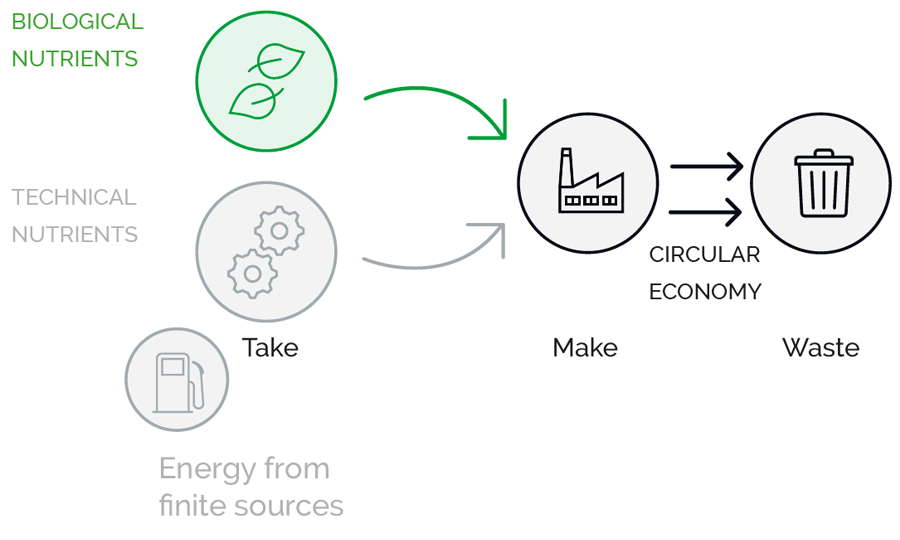

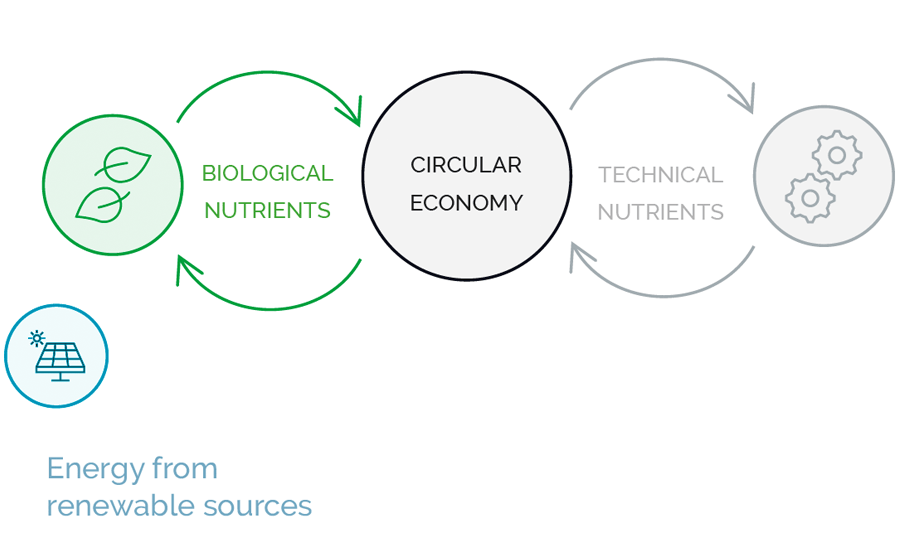

For a long time, our economy has had an open-ended setup with a linear material flow. In such a traditional setup, the raw materials are utilized to make a product, which at the end of its service/lifetime is disposed of and thrown away. In such an economy, materials end up with very little or no value. This consumes huge amounts of our common resources, making it unsustainable. In the case of concrete materials, this end up as construction debris, with the main application being landfill. However, before this the building may need to be demolished, and debris will need to be transported to the proper place, increasing environmental impact further. In a circular economy model, where extending lifetime and avoiding waste are the main assumptions, all materials are conserved and used as input for new products4. Such a state can be achieved through designing, maintaining, reusing, remanufacturing, refurbishing, and recycling with clear goals in mind.

For existing concrete infrastructure, this implies maintaining and prolonging their lifecycle, rather than replacing it with new builds – if safety and design standards are in place. To be able to extend their lifetime, it is essential to know their health condition. Traditionally, this has been carried out by visual inspections, which limit assessment to investigation of the surface of a structure, bringing any conclusions about internal issues only when the deterioration is already well advanced. The only way to find out about structural problems earlier, has been by the use of the coring technique, which is expensive, time-consuming, and weakens the structure on

which coring is performed even further.

The idea of Non-Destructive-Testing (NDT) assessment is not new and dates back to the end of the nineteenth century, becoming increasingly popular after WWII, with a growing number of techniques used for inspection. However, some of these techniques require immense experience for the proper interpretation of obtained data. Others are complicated, yet not reliable when it comes to the obtained results. Most require a significant workload for both: appropriate data gathering, analysis, and interpretation, as well as providing proper reporting.

Only some of these techniques give the possibility to obtain 3D visualization of the interior structure that leads to a better understanding and detection of possible defects. Also, along with the recent development of smartphone technology and the overall trend of digitalization, some of the commercially available devices allow for more repeatable and productive workflow.

Figure 1:

Linear v.s. circular economy

The foundation of deterioration

The most commonly used technologies in concrete construction for long span lengths, such as bridges or for thin slabs, are reinforced concrete and pre-stressed concrete. In both cases, strengthening is done with the implementation of steel elements: reinforcement with steel rods in the former and tendons in the latter. A decrease in the strength, and therefore maximum carried load, is generally caused by the deterioration of the concrete material, or corrosion of the steel elements. There are numerous reasons for the aging of the concrete constructions, such as construction faults, conditions of their usage, quality of used materials, but also environmental conditions, which can be roughly divided into mechanical, chemical, and physical factors, for example fatigue, impact, overload, alkali silica reactions, shrinkage, freeze/thaw, just to mention a few. Corrosion in steel is most often related to carbonation of concrete or/and chloride introduced corrosion due to de-icing salts or salts from the ocean.

Defects emerging on the surface can be easily identified by visual inspection, but the flaws inside a structure need more advanced methods to be revealed.

The importance of assessment

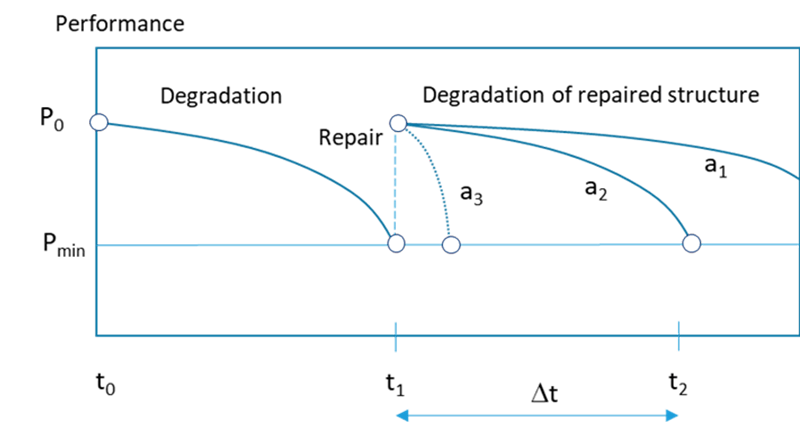

A structure is built with a fundamental performance requirement for a minimum period, as defined by the client. Performance can be defined in different ways. It might be related to structural safety, load carrying capacity, serviceability, durability etc. In figure 2. P0 refers to the performance at construction. Over time the structure might degrade and at t1 we have reached the lowest acceptable performance, where repair is needed. The remaining life of the repaired structure, t, depends on life strategies, budget, but also on correct assessment of a1 or a2. Choosing the wrong repair measure or basing the strategy on inferior assessment can even make the life of the repaired structure very short, a3.

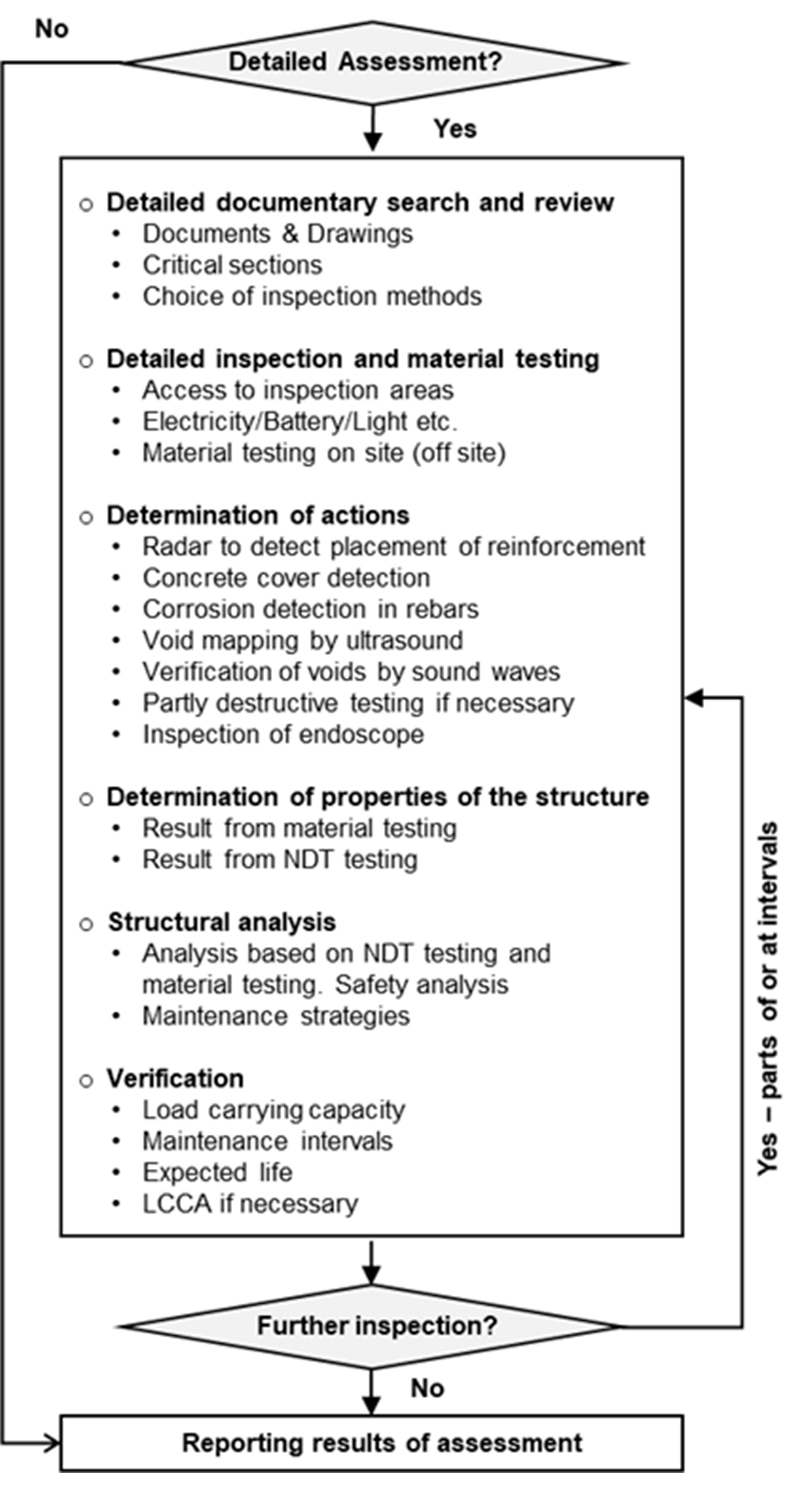

Concrete structures, and in particular bridges, need to be inspected regularly, to meet the safety and accessibility requirements of the users. To be the most efficient from a client and cost perspective, the guiding principles should be followed. In figure 3, general principles for maintenance, repair, and strengthening of the concrete structures are presented. It can be easily noticed, that the central part of the maintenance of the concrete structures is their assessment.

Figure 2:

Linear v.s. circular economy

Figure 3:

Possible flow chart for detailed assessment of concrete structures by the use of NDT

- Level 1 comprises a simple visual inspection carried out from the ground, boat, or at easily accessible places. You investigate concrete surfaces and measure carbonation depth and concrete cover. The most important tool at level 1 inspection is eyes/photos/film.

- Level 2, so-called extended analysis includes a detailed visual inspection of all concrete surfaces, as well as some measurements and material tests. In addition to level 1 also chloride content, crack widths, delamination and condition of reinforcement should be investigated. It may also be required to carry out potential measurements, bond, possible settlements and reinforcement

continuity. - Level 3 foresees an extensive analysis that includes the same type of measurements and tests as for Level 2, but more samples are collected, and often also NDT inspections are carried out to a larger extent.

However, it is recommended that the NDT procedure includes all three levels, as it can extend the understanding of possible problems, needs, or safety measures that should be applied.

Besides, it is a good practice to schedule an “NDT inspection calendar” for the “preventive maintenance”.

To summarize, it is imperative to periodically perform a comprehensive evaluation of any built infrastructure, and in particular such strategic elements, as public infrastructure. Both main construction components, made out of concrete as well as steel, need to get due attention. Diligent visual inspection is crucial; however, it does not provide a full picture, hence does not allow for completely accurate conclusions. Besides the investigation of the chemical composition that enables us to conclude the degree of erosion, it is important to scrutinize the interior of the structure for the sake of comprehensive understanding.

Methodology and equipment

Elop’s vision is to provide asset owners with smart products and solutions that will help them to improve safety, extend lifetime, minimize lifecycle cost, and contribute to an overall reduction in the environmental footprint of concrete structures globally.

As the built infrastructure gets older, the need for thorough assessment and understanding of its deterioration process and its influence on the building safety increases. The basis for efficient lifecycle management of the asset is to know its status, i.e. does the facility meet the requirements for safety, and if not, what does it cost to remedy, and when should it be done? In simple words, it is imperative to know what you have and what you manage. In particular, for concrete structures, such information is not possible to gain without in-depth NDT evaluation.

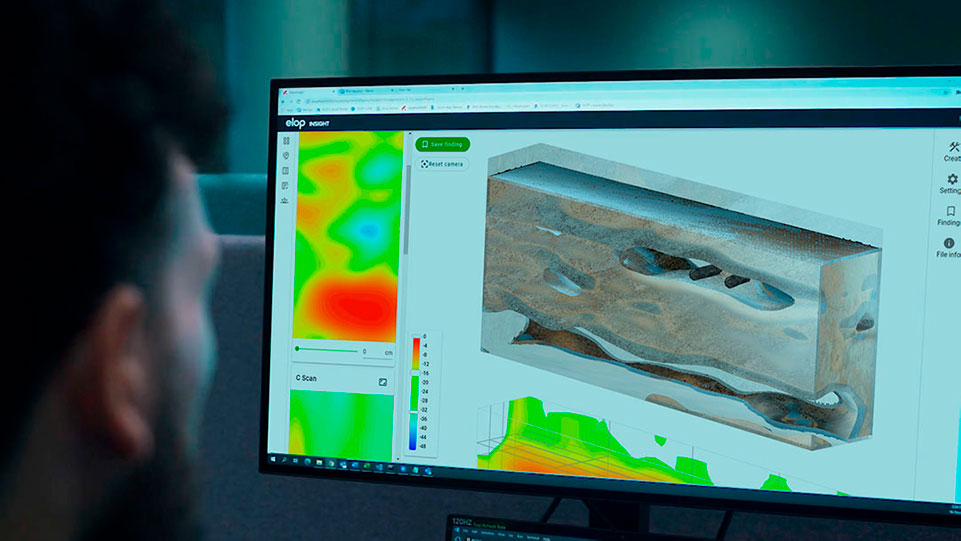

Elop has developed a new groundbreaking solution enabling accurate inspection, asset management, and structural health monitoring of concrete structures – the Elop Insight. The Elop Insight scanner rolls over the surface to be investigated, and a 3D scan of the interior structure is generated in real-time.

The novel Elop Insight solution gives the possibility to improve the current state of concrete assessment methodology. Thanks to ultrasonic technology, it can accurately help to identify the size and depth of existing defects within concrete structures including voids, honeycombs, delamination, air pockets, and internal cracking. The discussed methodology follows a typical assessment procedure (refer to figure 3), but is characterized by significantly shorter time-to-result, whilst at the same time maintaining higher accuracy compared to other techniques and methods supported by devices available on the market. While the scanner rolls over the surface, the ultrasonic waves are sent through the material, reflected at the interfaces between the concrete and the empty spaces within the structure, and received back by the receiving transducers. With the use of the Synthetic Aperture Focusing Technique (SAFT), the 3D live image of the interior structure is reconstructed. In addition, direct access to various 2D views gives a full visualization toolbox. Immediate cloud sharing capabilities allow for remote Team support when needed. Fully digital workflow eliminates all unnecessary manual steps increasing productivity, efficiency, and completeness of the overall process.

The strong focus of the Elop Team has been to deliver the best thought through and most pragmatic solution for NDT Inspections, bringing a series of advantages that make the ELOP Insight a solution of unparalleled effectiveness.

The following can be listed among the most important advantages.

Easy to handle

ELOP Insight scanner is a rolling device, therefore requires minimum physical effort to handle, no matter how the scanned surface is located, bringing the best comfort even if used for many hours. Its fundamental assumptions for the ergonomic design allow to gather precise data minimally exposed to errors resulting from the human factor. Immediate 3D visualization of the scanned object gives prompt feedback from the scanning process.

Software, designed to be simple to use and intuitive, with clear feedback during the scanning process, allows not only for short time-to-results every time, but short time-to-legitimate-results. A straightforward interface has the advantage of relatively short training required to master the device, even for relatively new users, allowing them to focus on the inspection, rather than being occupied with proper operation of the device.

All gathered data is transferred and stored in the cloud automatically, which also simplifies the post-inspection part of the process, removing such unnecessary steps as data transfer, or its backup.

Efficient

As every minute counts, the Elop Team designed the Elop Insight to be the most efficient and pragmatic solution available.

And, thanks to the data cloud storage, in the case of any doubts or if you just need support in the interpretation of data, you can engage your peers by remote teamwork. A fully digital workflow doesn’t take you away from the process of scanning. Elop Insight helps you to collect all the data you need, complete the documentation with notes or photos taken onsite, without the need of interrupting the process with additional manual steps, such as the use of a notepad, or

another device. Onsite, every minute of work is optimised to make it meaningful and worth the effort. Elop Insight also optimises your time offsite: The cloud based, Elop Insight web portal gives full access to data from anytime and anywhere. While the Elop Insight scanner is working on the next job, you may already be analysing gathered data and drawing conclusions, complete with the generation of a fully automated inspection report.

Removing many unnecessary interruptions from the inspection, simplifying it, and minimizing the chance for human-induced error, make the overall process time-efficient and pragmatic. Elop Insight is a cutting-edge, high-tech device, with the newest technologies employed. It is also designed with great care for fundamentals too – its robustness, IP54 class for dust and water protection, and a substantial range of operating temperatures makes it perfect even for the harsh environments of the construction site.

Live 3D models at hand

One of the invaluable advantages of the Elop Insight is Live 3D visualisation of the concrete structure. SAFT algorithm, the standard in the restoration of the image in the medical applications, gives a good visualisation perspective, revealing areas of interest. A set of filters allows for step-by-step analysis, and various views available at your fingertips are crucial for precise conclusions.

Data Clarity

The Elop Insight scanner has built-in mechanisms that help to maximize the quality of data, whilst at the same time minimising the number of outputs that need to be controlled and considered during the inspection work.

Software is key and a focus area for Elop. A practical and straightforward user interface and reliable data are given by default. ELOP aims to make sure that all Elop Insight users are, at any given moment, up-to-date and equipped with the latest features and software capabilities.

Continuous quality improvements for even smoother operation, delivering even more precise and reliable data in the most convenient and useful way.

Pressure sensors in the handles provide feedback to the user when the contact pressure between the scanner and the surface is not high enough, risking high-noise data. Calibration is the starting part of the inspection and clear feedback relating to the speed of rolling, assures that none of the gathered data is in any way lost or compromised when it comes to its quality.

All of these built-in mechanisms are part of the fully digital workflow, which not only shortens time-to-data ,but also removes any possible elements of the inspection process that are prone to any errors related to human inattention.

Finally, given the unparalleled productivity that is achieved due to the working (rolling) principle, as well as high-speed scanning, for the first time ever, it is possible to perform inspection on nearly 100% of the asset area. This unlocks the potential for covering the maximum surface area ensuring a high probability of detecting all suspicious areas that can be scanned again with high-resolution mode to obtain more details.

Fast and professional back up and support

The team of engineers, scientists, application specialists, and service engineers in Elop’s customer satisfaction center brings comprehensive support whenever it is needed in a professional and timely fashion to help you in any inspection challenge you may have. Elop is committed not only to the improvement of the sustainability of the construction industry, but also strives to make sure that Elop’s solutions are sustainable too. Any minute spent offsite by the Elop customers counts, and we are committed to making it efficient.

In summary, Elop Insight is an unsurpassed breakthrough when it comes to the NDT Inspection of civil assets, providing:

- Unparalleled Productivity of inspection due to the practical solution allowing for adaptation of the parameters as needed. Excellent ergonomic, industrial design is perfect for long hours of scanning, even in the most unforgiving conditions. Immediate 3D visualization and possibility of remote Teamwork provides an immediate solution to any inspection problem.

- Flexibility is expressed in the conscious ergonomic design, that is also perfectly adapted to the wide range of working conditions. Equally important is powerful

software of flexible architecture and with a well-thought through interface that allows for further development as needed but also frequent updates and new features delivered to the Elop Insight users regularly. - And peace of mind, provided by nearly any aspect of the design of the Elop Insight. Sturdy design, regular yet meaningful software updates that give unprecedented possibilities round it up. Cloud connectivity provides not only maximum safety for your data but also enables the remote Team support when needed. Live visualisation and built-in control mechanisms for the proper data gathering are invaluable when it comes to the assurance of a good job.

Reference projects

Voids and delamination on a wall structure An assessment of precast element working as formwork for in situ cast concrete has been carried out. The reason for the investigation was that a larger void had been found when drilling was made for fasteners.

In the assessment, the following methodology was followed:

- Overall visual inspection studying of documents and planning

- Simple investigation with both IE (Impact Echo) and UPE (Ultra Pulse Echo) to calibrate and investigate best strategies

- Dividing areas into sufficient small squares, but not too small due to time limitations. Here 250 x 250 mm was a good compromise

- Using IE to detect possible flaws in the concrete elements

- Using Elop Insight for more detailed investigation, and

- Verifying results with ES (Endoscope)

In total 85% of 3 000 m2 wall area was examined.

Large areas were found with delamination or honeycombing between the precast elements and the in-situ cast concrete. However, the size of the defects were small and the existing steel reinforcement is to a major extent covered by concrete. The reason for debonding is most likely either ice in the formwork, shrinkage of the in-situ concrete, temperature effects or a combination of these factors.

Conclusion

The newly developed ultrasound scanner and cloud-based software, ELOP Insight, is the most advanced and versatile device on the market allowing to detect and visualise any air pockets or voids within the concrete structure.

Here are a couple of points that need to be stressed:

- Such a high-tech, future-orientated device will not replace the expertise, knowledge, and hard work that every NDT Inspector puts into his job. But would help to make the asset inspection work more efficient, comprehensive, and meaningful.

- Every asset inspection still needs a multi-angular, comprehensive approach, but using ELOP Insight it can be optimised, focusing on the correct diagnosis whilst

minimising time and effort on such auxiliary activities as reporting and data organization, providing fully digital workflow. - NDT inspection is invaluable for the built infrastructure and needs to be esteemed by the knowledge and expertise, not the hours spent onsite. Therefor Elop is committed to helping to improve productivity at any possible step through employing smart software solutions.

That is not only for inspection and its preparatory role, but also intervention (repair) and quality control (post-repair).

- Elop Insight simplifies the overall assessment: such NDT evaluation might be complex but it doesn’t have to be complicated. Elop Insight is a smart solution that provides the capability of direct 3D live visualisation of the interior structure, which is of great help when it comes to data interpretation and overall productivity. Elop Insight is a great replacement for many of the currently used NDT techniques, making the whole process of the evaluation simpler, more effective, and less prone to human-related errors and mistakes.

- As one size does not fit all, so one technology will not be the answer to everything. However, Elop Insight is proven to be unmatched when it comes to the detection and visualisation of voids, air pockets, or honeycombing within the concrete structure. When used regularly on the asset monitoring its health, the preventive maintenance program focused on the extension of the asset lifetime can be set up.

Convenient and well-thought-through cloud data storage with access through the Web Portal interface, make it a perfect tool not only for one asset but to be a part of the asset management system.

Summarising, bulletproof technology incorporated into the bulletproof solution allows to get bulletproof data leading to the bulletproof conclusions. Stay safe.

Key takeaways

- It is not always possible to build “better” for the longer lifespan, sometimes the limiting factor is the environment. Nevertheless, it is possible to extend the assets lifecycle through diligent monitoring of its conditions, setting the regular checks, and executing preventive maintenance plan. Novel inspection solutions, such as Elop Insight, provide highly reliable data giving great fundament for conclusions, and its optimised, fully digital workflow revolutionises productivity. This is not to be underestimated given the scale on which the preventive maintenance program needs to be set-up if the circular economy should be achieved.

- Immediate 3D visualisation and the rolling principle of the scanner along with fully digital workflow make the Elop Insight solution revolutionary, transforming the NDT Inspection market segment. From having been sporadically used supportive technique, it becomes the central one in the assessment strategy, also given the speed and simplification provided with remote Teamwork principle.

- Given the amount of data that is collected while scanning, and the way it is being stored, it is a great start for the preventive maintenance and health monitoring not only for a specific asset but also as a predictive statistical mechanism for the other assets, or observed deterioration mechanisms.

Sources

[1] Global status report for buildings and construction, 2019

[2] ResearchGate, 2019

[3] PWC Global Construction 2025, 2018

[4] Circular economy in the Nordic construction sector, 2018